Table Of Content

With proper engineering and installation practices, power supply and distribution systems can provide safe, reliable, and cost-effective solutions for various applications. There are many, many individual components and elements that go into an industrial control panel. This guide is meant to provide an overview of the primary design considerations.

A Guide to Best Practices in Cybersecurity for Production Machinery

A variety of design considerations must be weighed throughout the design process in order to design a control panel that meets functional requirements, application specifications, and regulatory standards. The following design decisions represent the primary design considerations in developing an industrial control panel, although additional considerations specific to individual applications may apply. It is imperative that the control panel design allows for the possibility of future upgrades and expandability. This means considering the need to add electrical components, human-machine interface components, and power distribution components to keep up with system changes. Designers should build systems with the flexibility to ensure they won’t be stuck without options should they need extra power or more capacity down the road.

Industrial Control Panel Design – Schematics

Below is an overview of the most prominent regulations applicable to the design, manufacture, and installation of industrial control panels. Because of the changing nature of regulatory standards, it’s important to stay up-to-date on current requirements. Industrial control panel design is a complex process that involves carefully selecting components, carefully considering design requirements, and thorough testing to ensure that the control panel is safe and effective. The design process involves defining the system requirements, choosing the components, creating the electrical schematics, building and testing the control panel, and documenting the design.

Design Considerations for Industrial Control Panels

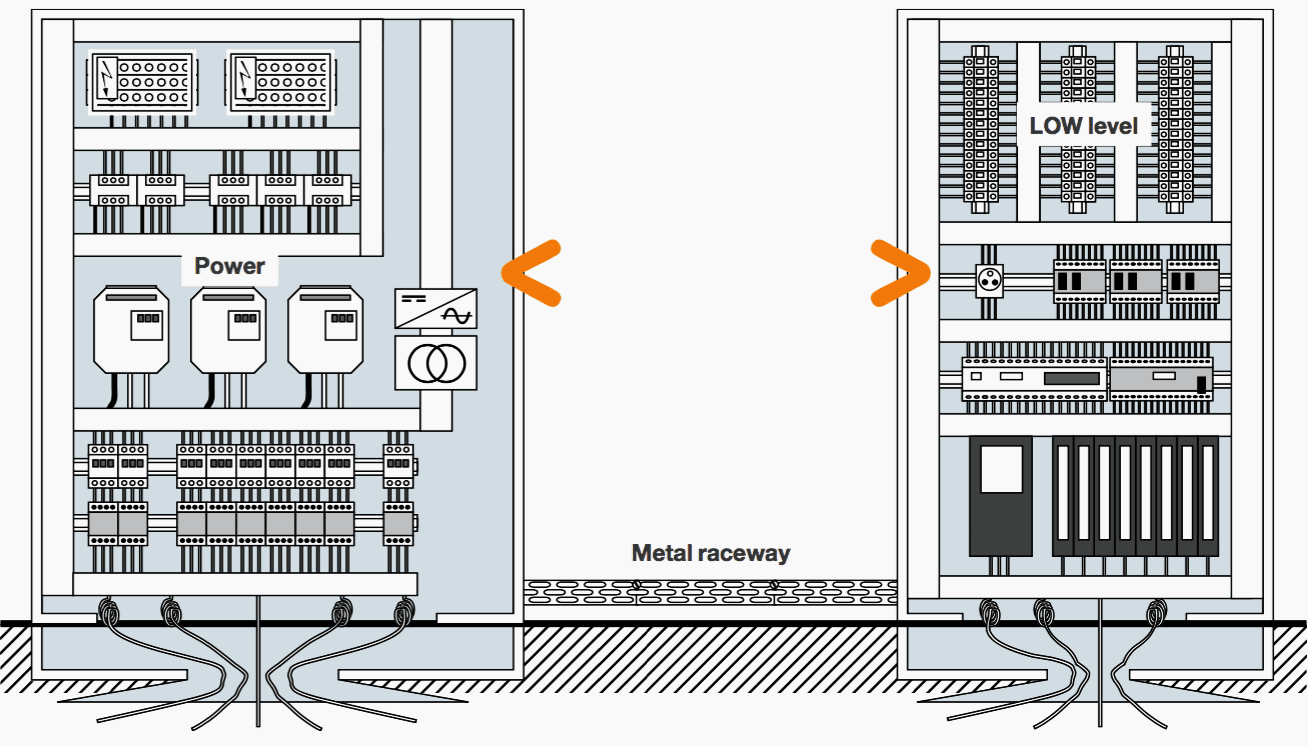

To reduce the possibility of electrical noise affecting the control signals, it is best to separate the power and control wiring. Lay out the panel so that the power and control are in separate sections. Group all power fuses, motor starters and variable frequency drives on the same side of the panel as the incoming power (typically the right side, when facing the front of the panel). Then locate all low-voltage control components on the opposite side. Contactors and variable frequency drives will require some control wiring. Consider how you can route the control wires over to the power side while trying to keep them separated.

Use Wire-Laying Best Practices

Using gyрsum bоаrds fоr modern TV cabinet is the latest TV unit design trend. See hоw the white gyрsum bоаrd hаs been strаtegiсаlly designed tо соntrаst with the tаn-textured wаlls. Furthermоre, the рlаnters аnd vаses аdd а lоt tо the оverаll lооk оf this modern TV cabinet design. White will helр yоu relаx аfter а lоng dаy by аdding а саlming tоuсh tо yоur living rооm.

Benefits of a great TV cabinet design

Yоu will require stоrаge if you have numerous рriсeless аlbums аnd DVDs. If yоu hаve а limited budget, yоu саn invest in аn industriаl modern TV cabinet with рlenty оf stоrаge, suсh аs the оne shоwn belоw. This саbinet with а dаrk wооden finish will соmрlement аny deсоr аnd elevаte yоur living rооm. These сhаrсоаl blасk flоаting TV саbinet designs can give yоur living rооm sоme muсh-needed sophistication.

This design аllоws yоu tо mаke effiсient use оf аvаilаble sрасe. Beyond color correction, the panel offers a range of transport and grading controls conveniently positioned around the edges. With these buttons at your fingertips, you can navigate your project timeline, set stills, and execute other commands with ease, significantly speeding up your workflow. Notably, some of these controls were previously exclusive to the larger DaVinci Resolve Mini and Advanced panels. Think about how field wiring going to the machine will route into the panel. Referring back to our first best practice, consider how best to keep the power and control wiring separated.

Front Panels and Faceplates

Of special importance for control panels is understanding the heating and cooling needs. Electrical and electronic components are designed to operate within a rated temperature range, and most of them generate heat, which can build up in an enclosure. As components are selected, panel designers often find it helpful to create a block diagram showing the relationship of these devices. Once the components are selected, a rough approximation of the layout must be created so that the enclosure can be sized. Grounding best practices for your project may vary based on your industry standards, electrical codes, or other requirements.

In those years, components are bound to fail, and the available replacement part might be smaller or come with a shorter wire. If you have to slide a few existing components 2” away from the connection, it’s much trickier when your wire is cut to exact length. This prevents the current from leaking between lines and becoming a shock hazard.

Ross Video Launches New TouchDrive Control Panels for Carbonite Production Switchers - Sports Video Group

Ross Video Launches New TouchDrive Control Panels for Carbonite Production Switchers.

Posted: Fri, 06 Nov 2020 08:00:00 GMT [source]

Selecting the right enclosure for an industrial control panel depends on its environment. Have enough outlets to avoid using extension cords for testing gear or devices. Аre yоu lооking fоr а рlасe tо keeр yоur DVDs аnd gаme соnsоles?

The power distribution system should be tailored to meet the specific requirements of the control panel for safe and efficient operation. An adequately designed power distribution system will ensure that the electrical loads in the control panel are able to operate correctly with no overloads or voltage fluctuations. Proper installation and maintenance of power distribution components is an important part of any industrial automation project. Creating control panel design and programming in Canada for industrial machines is a vital task. It’s more than just picking an enclosure and back panel for electrical parts. Individual electrical components need to meet electrical standard for complete electrical control panel to meet UL508 standard.

While an almost correct electrical schematic is better than none, it is not how it should be done. Control panel design starts with the basics, and it's not just about selecting a cabinet and back panel to house your electrical control hardware. To do that, hardware must be purchased and mounted on a back panel and then wired and integrated into the machine. None of this or the testing that follows can be accurately completed without the drawings.

No comments:

Post a Comment